Projects

Are you a company with control as your core technology?

Than by using Spectrum services, you can leverage our experience and knowledge to improve the performances of your product and shorten the development cycle!

Research:

Traditional scanning mirrors are designed to operate under resonance conditions thus exhibiting low losses and requiring a small driving force/torque.

Indeed these devices can achieve large scan angles and low driving forces creating a sinusoidal scanning motion. For some applications, a uniform scanning rate is required and operation in a single resonance frequency does not provide satisfactory results. Unfortunately,

the requirement to obtain a non-sinusoidal periodic motion profile increases the required forces to a degree depending on the scanning frequency and the physical behavior of the device. In this work we introduce a novel idea with which a nearly triangular shaped scanning profile is obtained by suitable synthesis of the structural dynamics.

A new automatic method to tune the parameters of high order linear controllers is presented. The auto-tuning is achieved by minimizing, without constraints, a cost function that is related to the open loop shaping problem.

The effort demanded from the designer is similar to that required to tune a low order controller such as PI or PID. The capabilities of the new method are demonstrated on two examples.

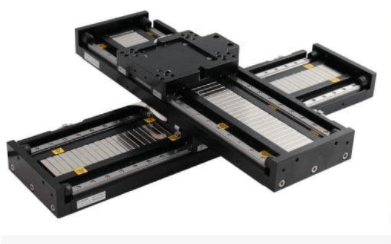

Identification and Modeling of Contact Dynamics of Precise Direct Drive Stages

The aim of this paper is to develop identification that is capable of capturing the characteristics of nonlinear tangential elastic and friction forces arising in submicron motions. Using novel Hilbert transform based signal processing and making use of the intimate relations between internal elastic and friction forces, the latter can be simultaneously recovered from measured data. The experiments were performed on a stage equipped with linear motors, while being driven by slow, quasi-harmonic excitation at frequencies of 1–40 Hz. The identified elastic force incorporates the inevitable nonlinear nature of the stage. The proposed identification technique can be useful for the analysis of modeling contact dynamics between moving and sliding parts in situ. This technique can possibly develop improved closed-loop control algorithms.

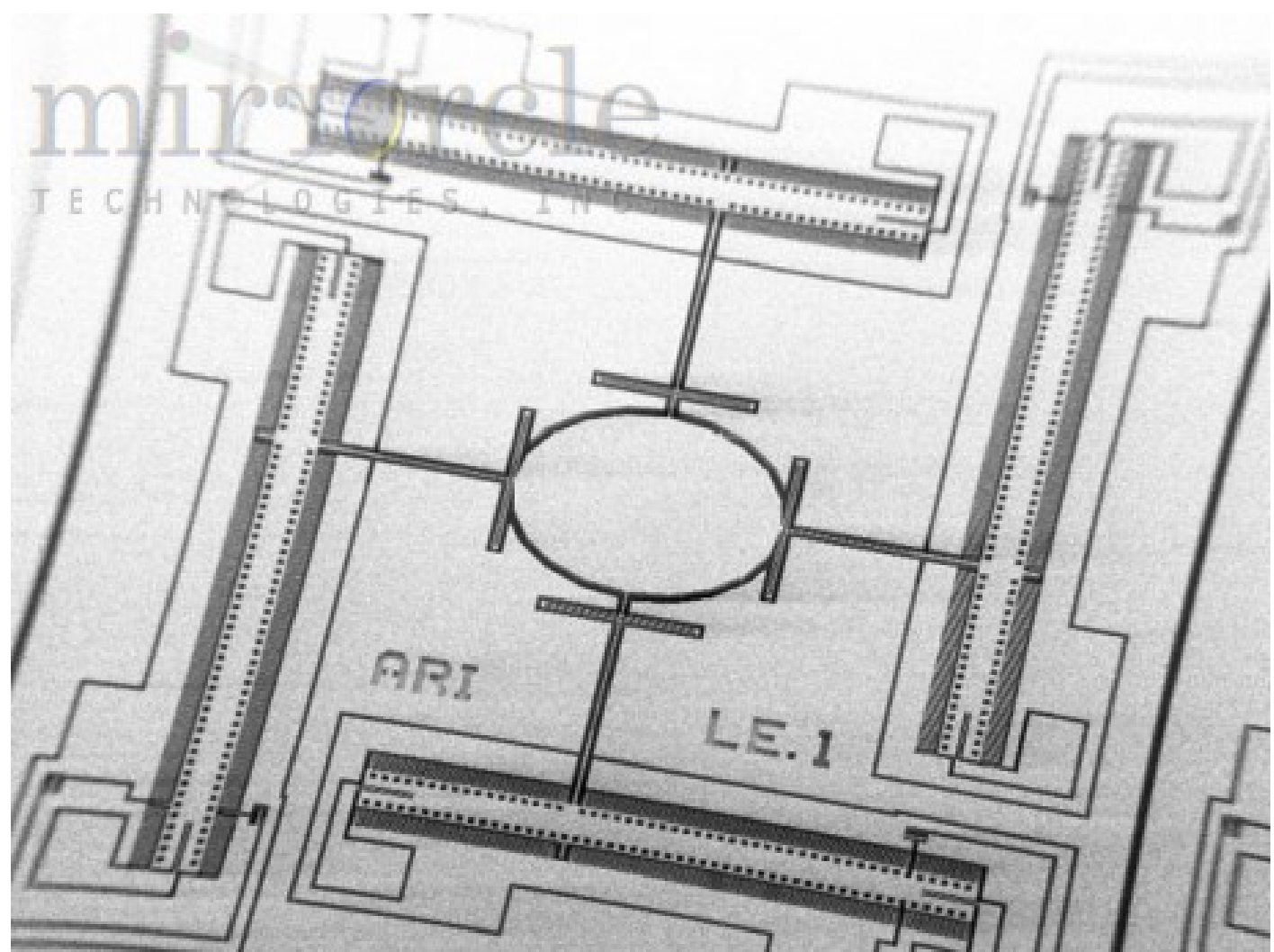

The Fast Steering Mirror (FSM) is commonly used for many applications. Among the applications one can count optical switches, image

rendering, beam positioning, tracking, etc. The FSM consists of a mirror

placed on a torsional flexure. Together with an actuation mechanism it can

perform angular motion. The actuation mechanism is mostly electromagnetic

for macro scale FSM, or electrostatic, or micro electromechanical system

(MEMS), in a micro scale FSM. It can be operated in open or in closed loop.

The flexure plays the role of torsion spring that together with the mirror

inertia generates an essentially 2nd order system plant with weakly damped

poles, i.e. with resonance dynamics.

If your team needs control training,

we have ready courses.